Co-gen chemistry personnel often face additional challenges over those encountered by their power plant counterparts. Careful planning and good vigilance are necessary to minimize corrosion and fouling in these systems.

In Part 1 of this series, we examined methods to produce high-purity water for high-pressure power and co-generation boilers. Corrosion and scale formation are very real threats without pristine makeup. Less rigorous makeup methods are often suitable for lower-pressure co-generation or industrial steam boilers, but much too often poor attention is given to makeup system operation and maintenance, with boiler tube failures being the result. We examine some of the most important issues in this installment. Ss Flexible Pipe

Figure 1 provides a basic schematic of a common co-generation configuration.

Figure 1. Generic flow diagram of a co-generation system. The blowdown heat exchanger and feedwater heater may not be present in some configurations. Note the multiple condensate return lines. Illustration courtesy of ChemTreat, Inc.

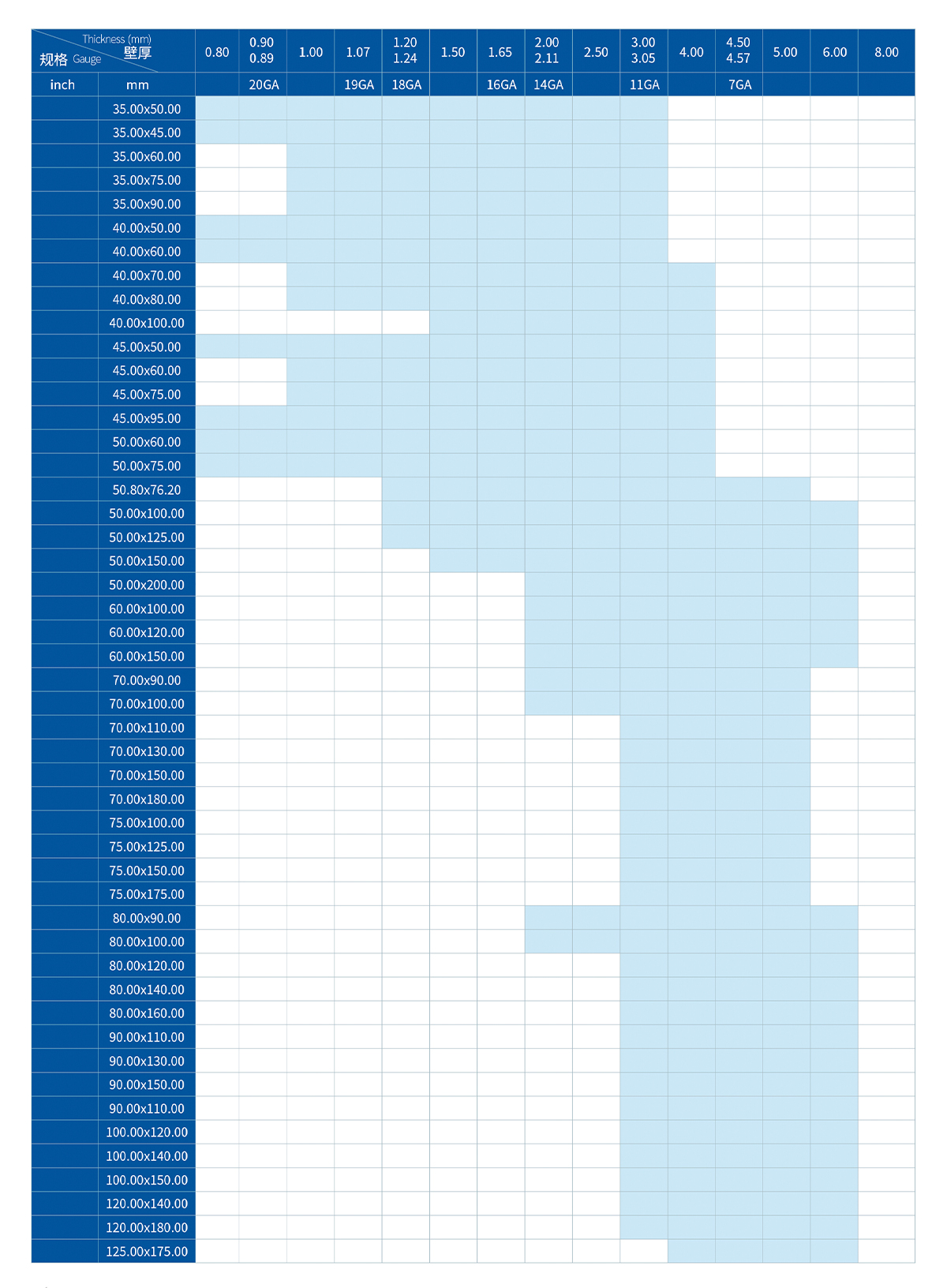

Depending on boiler pressure and design, and the processes served by the boiler steam, makeup treatment may range from sodium softening to reverse osmosis to perhaps even the high-purity arrangements outlined in Part 1. For steam generators under 600 psig pressure, sodium softening, often combined with downstream equipment for alkalinity removal, is common. Figure 2 below is an extract taken from the recent revision of the American Society of Mechanical Engineers (ASME) industrial boiler water guidelines (1). This extract provides insight on impurity level limits for low- to medium-pressure water tube industrial steam generators. The complete guidelines are available from the ASME at very reasonable cost and should be in the library of any industrial plant with steam generators.

Figure 2. Data extracted from Table 1, Reference 1 – “Suggested Water Chemistry Targets Industrial Water Tube with Superheater”

While power plant chemists are (or should be) familiar with stringent requirements for their high-pressure units (which we will return to in later parts of this series), several guidelines in this extract stand out for lower-pressure boilers. These include:

Let us consider these items in greater detail with help from References 2 and 3.

A very common comment/question that steam generation chemistry experts receive from industrial boiler operators is, “We are suffering repeated boiler tube failures, can you help us find the source.” One of the first items a specialist will typically examine is the sodium softener. Time after time, the consultant will learn that softener upsets have been common but that the plant continues to operate with out-of-spec makeup water going to the boiler. Figures 2 and 3 illustrate the typical result of softener upsets and malfunctions.

Figure 4. Bulges and blisters in a boiler tube from overheating due to internal deposits. Photo courtesy of ChemTreat, Inc.

A common malady at many plants, which this author has directly observed on several occasions, is an intense focus by plant personnel on process chemistry and engineering with insufficient attention to steam generators (and cooling systems) until failures begin to cause unit shutdowns that affect production. Water and steam are the lifeblood at many plants, and to neglect these systems puts plant operation and sometimes employee safety at peril.

Apart from hardness capture, even well-operated sodium softeners by themselves remove no other ions from the makeup water. In low-pressure boilers with good blowdown control, most impurities may be manageable. However, issues regarding alkalinity (the alkalinity in raw water is usually in the bicarbonate, HCO3–, form) deserve additional discussion.

HCO3–, upon reaching the boiler, in large measure converts to CO2 via the following reactions:

2HCO3– + heat → CO32- + CO2↑ + H2O Eq. 1

CO32- + heat → CO2↑ + OH– Eq. 2

The conversion of CO2 from the combined reactions may reach 90%. CO2 flashes off with steam, and when the CO2 re-dissolves in the condensate can increase the acidity.

CO2 + H2O ⇌ H2CO3 ⇌ H+ + HCO3– Eq. 3

Long-term carbon-steel corrosion may be the result.

Figure 5. Carbonic acid grooving of a condensate return line. Photo courtesy of ChemTreat, Inc.

Furthermore, the iron oxide corrosion products will transport to the steam generators and form porous deposits on boiler tubes and other internals. These precipitates can become sites for under-deposit corrosion (UDC) fed by impurities in the boiler water. UDC generally increases in severity with increasing boiler pressure and temperature. At high-pressures, UDC can lead to hydrogen damage, a very insidious corrosion mechanism.

Some sodium-softened makeup systems also have a forced-draft de-carbonator or split-stream de-alkalizer to remove most of the bicarbonate alkalinity, but even with this equipment the remaining dissolved ions in the raw water still enter the boiler makeup. These impurities reduce the allowable cycles of concentration in the boiler, which leads to increased blowdown. If not properly monitored and controlled, they may cause corrosion or increase the dissolved solids concentration in the boiler steam. Accordingly, becoming more popular is reverse osmosis (RO) for makeup water treatment. Even single-pass RO will remove 99% or greater of the total dissolved ions in the makeup water.

Figure 6. Basic design of a single-pass, two-stage RO. The designation two-stage comes from treatment of the first stage reject in a second stage. (3)

As we discussed in Part 1, addition of a second pass to the RO system with downstream polishing by ion exchange or electrodeionization produces makeup suitable for even the highest-pressure steam generators.

Steam generators that solely produce power nearly represent (usually) a closed circuit. A tight system may only have 1% water loss. The most common source of impurity ingress is a leaking tube or tubes in the steam surface condenser. (Units with air-cooled condensers offer other factors to consider.) So, with a good on-line chemistry monitoring system and attentive plant personnel, upsets can usually be quickly corrected. The situation is frequently much different in co-gen units, where condensate could be coming back from any number of chemical heating/reaction processes. Consider the following case history.

A number of years ago, the author and a colleague were invited to an organic chemicals plant that had four 550-psig package boilers with superheaters. The steam provided energy to multiple plant heat exchangers, with recovery of most of the condensate. Each of the boiler superheaters failed, on average, every 1.5–2 years from internal deposition and subsequent overheating of the tubes. Inspection of an extracted superheater tube bundle revealed deposits of approximately ⅛–¼ inches in depth.

Additional inspection revealed foam issuing from the saturated steam sample line of every boiler, whose cause became quickly apparent. Among the data from water/steam analyses performed by an outside vendor were total organic carbon (TOC) levels of up to 200 mg/L in the condensate return. Contrast that with the <0.5 mg/L feedwater TOC recommendation in Figure 2. No treatment processes or condensate polishing systems were in place to remove these organics upstream of the boilers. Based on the TOC data alone, it was easily understandable why foam was issuing from the steam sample lines, and why the superheaters rapidly accumulated deposits and then failed from overheating.

To protect steam generators from what could be a wide variety of impurities, careful planning is needed to determine, among others, what contaminants and in what concentration may be in the return condensate, can the impurities be economically removed by some form of condensate polishing system, and what streams may need diversion directly to the wastewater treatment plant? The latter issue, of course, influences the size and treatment methods of the wastewater system. Also, condensate dumping to the WWT plant requires increased makeup water production and a larger system in that regard.

Another important issue with co-gen and industrial steam units is feedwater dissolved oxygen control. In September and October of 2022, Power Engineering published a four-part series by the author on the importance of controlling flow-accelerated corrosion (FAC) in combined cycle heat recovery steam generators (HRSGs). (4) Because these high-pressure HRSGs require high-purity makeup (cation conductivity ≤0.2 mS/cm), and typically have no copper alloys in the feedwater system, the recommended chemistry calls for a small amount of dissolved oxygen (D.O.) in the feedwater with no oxygen scavenger (the better term is reducing agent) feed. For units with deaerators, it may be necessary to close the deaerator vents to help maintain a D.O. residual in the economizer circuits. Supplemental oxygen injection may also be required. For those who review this series, note that these guidelines are part of a feedwater chemistry program known as all-volatile treatment oxidizing (AVT(O)).

However, because the condensate return purity in co-gen and industrial steam generators often does not meet high-pressure feedwater guidelines, AVT(O) is usually not acceptable. The feedwater network may also contain heat exchangers with copper-alloy tubes, which further negates AVT(O) as a potential treatment program. Accordingly, a standard requirement is feed of an alkalizing amine to maintain pH within the range shown in Figure 2 plus mechanical deaeration and reducing agent/oxygen scavenger feed to maintain very low feedwater D.O. concentrations. This in turn necessitates accurate monitoring for feedwater iron (and at times copper) corrosion products to fine-tune chemical treatment programs. The author and colleagues have reported on these issues in previous Power Engineering articles. (5, 6)

Note: The Electric Power Research Institute (EPRI) has published a comprehensive book on flow-accelerated corrosion that is offered to EPRI members and non-members alike. (7)

Co-generation is becoming increasingly popular for power production and process heating at many facilities, in large part because the net efficiency is much higher (and corresponding carbon dioxide emissions are lower) than for traditional power generation. (8) However, co-gen chemistry personnel often face additional challenges over those encountered by their power plant counterparts. Careful planning and good vigilance are necessary to minimize corrosion and fouling in these systems.

Brad Buecker is president of Buecker & Associates, LLC, consulting and technical writing/marketing. Most recently he served as Senior Technical Publicist with ChemTreat, Inc. He has over four decades of experience in or supporting the power and industrial water treatment industries, much of it in steam generation chemistry, water treatment, air quality control, and results engineering positions with City Water, Light & Power (Springfield, Illinois) and Kansas City Power & Light Company’s (now Evergy) La Cygne, Kansas station. His work also included 11 years with two engineering firms, Burns & McDonnell and Kiewit, and he also spent two years as acting water/wastewater supervisor at a chemical plant. Buecker has a B.S. in chemistry from Iowa State University with additional course work in fluid mechanics, energy and materials balances, and advanced inorganic chemistry. He has authored or co-authored over 250 articles for various technical trade magazines and has written three books on power plant chemistry and air pollution control. He may be reached at beakertoo@aol.com.

50mm Stainless Steel Pipe Power Engineering®️ is the voice of the power generation industry including news, exclusive articles, and in-depth reviews. Subscribe today to receive critical information and industry updates to remain competitive in today’s market.