MULTIVAC announced the release of the new B 625 chamber belt machine. The B 625 allows the packing of various flat products more quickly, easily and securely than before. With two sealing bars, which are integrated seamlessly into the base plate in the sealing area of the machine, it is now possible to achieve a sealing height of 0 mm.

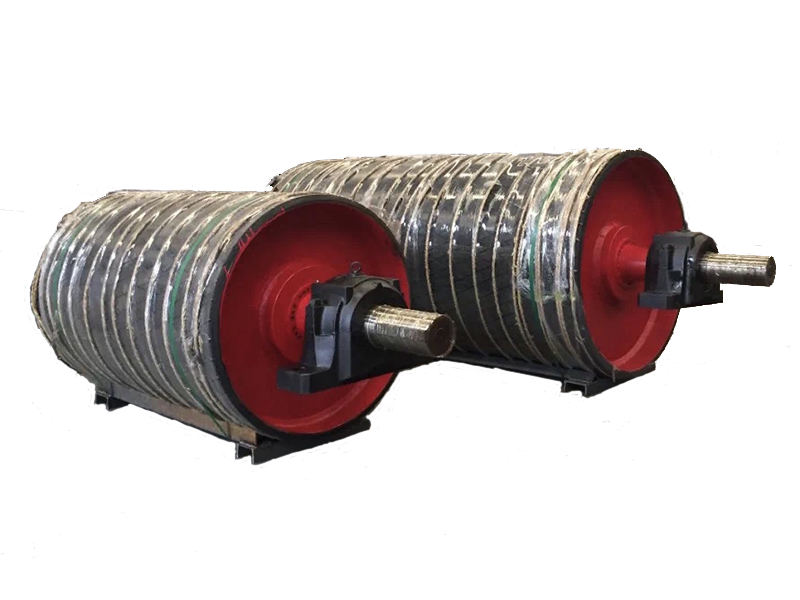

The new model version stands for even greater security and speed in the packaging process, since the pouch necks lie completely flat during evacuation and sealing, meaning that, compared to the standard sealing height of at least 25 mm. the pouch necks are no longer bent. The product and infeed transport into the chamber is also more reliable since interference areas have been eliminated and friction points on the infeed plate reduced to a minimum. MULTIVAC states that another benefit of B 625 is temperature-controlled impulse sealing (TI), which ensures that a constantly high level of seal quality at lower energy requirements is achieved—even in non-top mode. Parallel Idler

MULTIVAC has decoupled the automatic infeed conveyor from the packaging process to increase efficiency. This enables the chamber belt machine to be loaded automatically, so that even higher throughput can be achieved with fewer personnel, and even where the loading takes place manually, using just one person for loading significantly increases efficiency.

The B 625 is designed in the MULTIVAC Hygienic Design and therefore meets hygiene standards. The chamber lid, which can be swung manually and adjusted in any position, makes ergonomic access to the inside of the chamber very easy, as well as facilitates maintenance of the chamber belt machine and saves time on cleaning. This is reflected in reduced downtime for necessary service work. In addition to this, the robust and durable construction of the packaging machine is a further guarantee of high performance and efficiency.

You must have JavaScript enabled to enjoy a limited number of articles over the next 30 days.

Sponsored Content is a special paid section where industry companies provide high quality, objective, non-commercial content around topics of interest to the Food Engineering audience. All Sponsored Content is supplied by the advertising company. Interested in participating in our Sponsored Content section? Contact your local rep.

Our session will dive into real-world scenarios and practical examples, demonstrating how effective recipe management and simulation can drive innovation and efficiency in your enterprise.

For webinar sponsorship information, visit www.bnpevents.com/webinars or email webinars@bnpmedia.com.

Combining scientific depth with practical usefulness, this book serves as a tool for graduate students as well as practicing food engineers, technologists and researchers looking for the latest information on transformation and preservation processes as well as process control and plant hygiene topics.

Copyright ©2023. All Rights Reserved BNP Media.

Conveyor Parts Design, CMS, Hosting & Web Development :: ePublishing