Control unit supplies cold water to the mold only in the cooling phase.

The Microgel Syncro from Frigel is a new press-side unit that the machine builders say revolutionizes the temperature control method for injection molding. Battery Controller

Frigel says Microgel Syncro technology enables a drastic reduction in cycle time (up to 40%), while maintaining the surface quality, dimensional characteristics and mechanical performance of the finished product. The cut in total cycle time is accomplished thanks to the reduction of the cooling time only. This result, achieved through the digital synchronization with the molding process, requires no modifications to any of the molding parameters, making the system communicate with the press while remaining completely autonomous and easily implemented by the operators.

Compared to the traditional methods, the Syncro control unit supplies cold water to the mold only in the cooling phase, drastically reducing its duration. The advantages for the processor include increased productivity and profitability of the single production cell, with an average investment payback time of less than six months.

The Microgel Syncro product line features more than 10 models, with cooling capacities from 16 kW to 56 kW and heating capacities from 12 kW to 24 kW.

Frigel has also expanded its Adiabatic product family line with the Ecodry 4DK range, designed to enable flexible configuration of modular adiabatic solutions for small to large plastic processing plants. The series is characterized by a high-efficiency humidification system and a new generation of EC fans which, combined with a more effective dry cooler, obtain a new level of compactness in a powerful new adiabatic cooler product line.

The new Ecodry 4DK is designed to integrate easily into existing Ecodry 3DK systems, of which Frigel has an existing installation base of thousands of units. In addition to responding to the new needs of industries, it also offers energy efficiency, sustainability and saving of raw resources such as water.

Frigel also unveiled its 3PR 4.0 product platform, which is said to provide complete control of Frigel central cooling systems. The 3PR 4.0 control meets the needs of processors to supervise and manage the entire cooling system from a single control point. All the connected central system components are controlled via a control panel that has been designed specifically for Frigel systems. The 3PR 4.0 is available in two versions, Lite and Premium, depending on the size of the system and the equipment to control.

Hasco says the plugs, which are used for diverting flows in temperature control systems and sealing drilled holes, are ideal for use in medical and clean-room spaces.

Günther unveiled a new hot runner temperature controller and a specialized hot runner built specifically for the Babyplast line of molding machines at K 2022.

Mokon has introduced the Xchange-Therm line with customizable water temperature controls and combination heating and chilling units offering temperature ranges from -20° to 300°F.

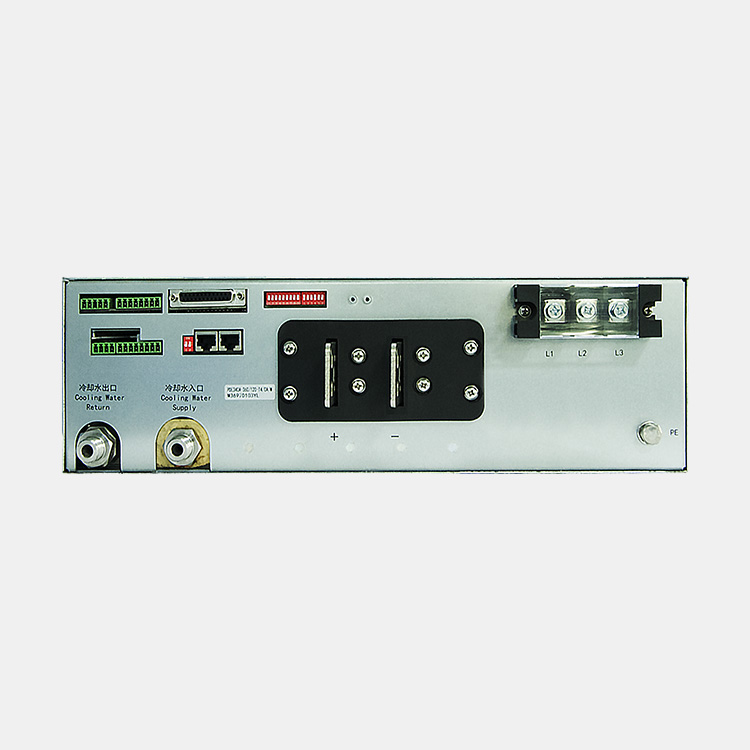

Three-Phase Power Controller © 2023 Gardner Business Media, Inc. Privacy Policy [Log On]